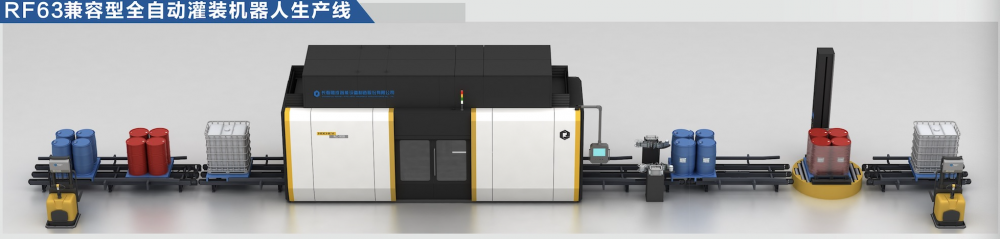

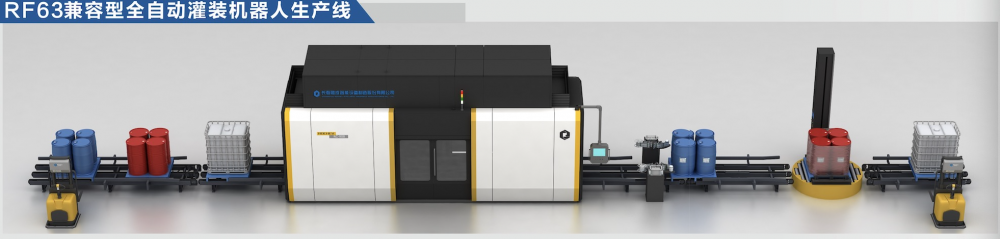

Product name : Anti-corrosion Filling Machine

Product Description : Anti-corrosion filling machine is a machine specially developed for the filling of corrosive liquids and cosmetics that cannot contact with metal liquids. - Rochiev RF63 equipment uses non-metallic materials, the liquid through the part is more PTFE material, the external exposed metal parts (such as: cylinders, motors, etc.) are used special anti-corrosion processing process to ensure that the equipment long-term use.

Scope of application : The anti-corrosion filling machine is suitable for the filling of liquid products that are easy to foam and froth, such as pesticides, preservatives, iodophors, etc., and liquid products of related properties, including various oils with low concentrations. , Pesticides and non-gas liquid beverages for automatic Filling Machines. The device's filling containers are suitable for filling various types of square bottles or barrels, round bottles or barrels.

Filling machine customer filling effect display

Equipment features :

1. The Automatic Filling Machine uses a turbine flow sensor (a kind of flow sensor) and a counter to control the filling.

2, with anti-drip system, no bottle no filling.

3, filling a wide range of bottle types, high filling accuracy.

4, the machine is an in-line structure, the use of light, machine, electricity, pneumatic principle, by the counter to control the filling volume, with a filling tube dive submerged wall device to eliminate the bubble generation.

5, filling volume from 1L-25L, filling accurate, fast, no leakage.

6, the price is lower than the same industry Filling Equipment.

The continuous development of liquid seasonings has highlighted the advantages of the fast liquid filling machine equipment:

Liquid filling machine http://WWW.ROCHIEV.COM

Installation debugging :

1. Placement: Select a place where the interior is flat and dry, and place the host and the transfer table after the opening. The main machine is on the inside of the conveyor table so that the filling head is vertically above the center of the conveyor table.

2. Install the conveyor: Install the bottom of the conveyor belt and the column stably. The bottom bolt can be adjusted slightly. Check the elasticity of the conveyor chain plate, and turn on the power (the back of the main power box of the code source line plug). The conveyor belt should rotate smoothly and the speed regulation is effective.

3, configure the power: This equipment uses a voltage 220V single-phase three-wire power supply, current 3A. When users access the power supply, they must have reliable grounding to ensure personal safety.

4. Configuration gas source: The gas source used in this equipment is 0.4-0.6MPa. The user-configured gas source drug is stable and ensures the uniformity of the cylinder movement to achieve accurate filling effect.

5, installation of photoeye: According to the installation position on the table to fix the photoeye, each group of the shooting position to be accurate, to achieve accurate counting effect.

Technical parameters :

| Drums /IBCs | 10L & 50L |

| Bunghole Alignment | Mechanism |

| Weight range | 2kg-60kg |

| Filling Capacity | 100-600 Drums/H |

| Filling Error | ±0.1kg |

The working principle of the device :

A. First fast and slow double flow efficient filling; Automatic induction capping machine

B, digital display directly set the filling volume; PLC program control, inverter speed linear filling

C, high-precision volumetric flow meter, accurate and reliable quantitative; vacuum suction double anti-drip

Tips : Precautions for equipment maintenance

1. The machine body is stainless steel, do not use a sharp, hard tool to scrape the surface.

2. The cylinder is lubricated at the factory. Do not open or add any lubricant.

3. Before cleaning the piston filler, clean the remaining product and then fill the drum with mild detergent. The company recommends using warm water. Use soapy water, Alcohol, or other cleaning fluid if needed.

4, when removing the piston and remove the fixing screw at the same time, so as not to affect the other when the first one is removed